Along with the popularity of non main lamp lighting design, many designer use the “led strip” to light up the room in the indoors decoration to create a rich color and bright or dim lvel visuality.

When you buy the led strips, many supplier said the 220V led strip is easy to break and it better to buy the DC12V/24V led strip for longer lifespan,. Let’s analyze this scientifically.

The difference between High Voltage and Low Voltage led strip

The Length is different

The upper picture is the common led strip and the voltage is usually in DC12/24V, Some led strip have the pipe is installed on the ceiling to protect the humidity and dust, this one is eacy to clean. And if installed into the aluminum profile for indoors decoration, the IP20 is more cost-effective.

The low voltage led strip is only can be 5M/reel because of the FPC is thin and the current per meter is can not very big. If the project need very long led strip, it will need to use more led power supply and connect more led strips with parallel connection. Besides, some constant current led strip can be 20M/reel with thicker FPC(e.g:30Z) to enlarge the alibity of bigger current passing.

The high voltage led strip normally in AC220V, it’s reel length and max run from one end is by 50-100M. Relatively speaking, the high voltage led strip can be higher power consumption, and its lumen/m reach 1000LM/M or even 1500LM/M.

Difference of cutting unit

The low voltage led strip can be cut on the cutting mark(knife mark), and the cutting length is based on the voltage, eg:the DC24V led strip is by 6leds of 10cm but the DC12V is 3leds of 5leds(based on the same led qty/M, eg:SMD2835 60LED/).

The high voltage led stripnormally 1M or 2M for a cutting unit, it’s cutting only by 1M or 2M but can not cut without cutting mark or the unit will not work. If we need 2.5M led strip, the main operation is to cut 3M and use black sleeve pipe to cover the other 0.5M to avoid the part is too bright.

Applied place is different

The low voltage led strip is very easy to install with the back tape and adhere to the place need to install, such as cabinet and cover, corner etc, and can bend as the shape for the project effect.

The High voltage led strip installed by the silicone or stainless steel clips and screws. Because it’s voltage is AC220V, it would be dangerous to install on the steps or guardrill that human can touch directly. The suggested place for high voltage led strip is the ceiling or the cove that can not touch directly and the high led strip must IP65/67 rating with the silicone pipe.

The Led Power Supply is Different

The low voltage led strip is need to install the DC power supply and test until the output voltage is same or clear to the led strip voltage(±2V) which the most important in the led strip installation.

But the high voltage led strip normally connect the AC power supply, it’s only need to plug in the AC220V and the led strip will work.

Why Low Voltage Led Strip More Reliable

From the description we have known that the key features about the high voltage and low voltage led strip, but why the low voltage led strip more reliable, let’s find our “Physics Book” in the middle school.

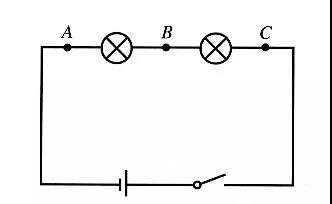

Firstly, we have to know the led strip emitting from the led chip on the FPC, and the led of each cutting unit is series connection and parttake the voltage averagely. LIke the circuit we learned in the middle school:

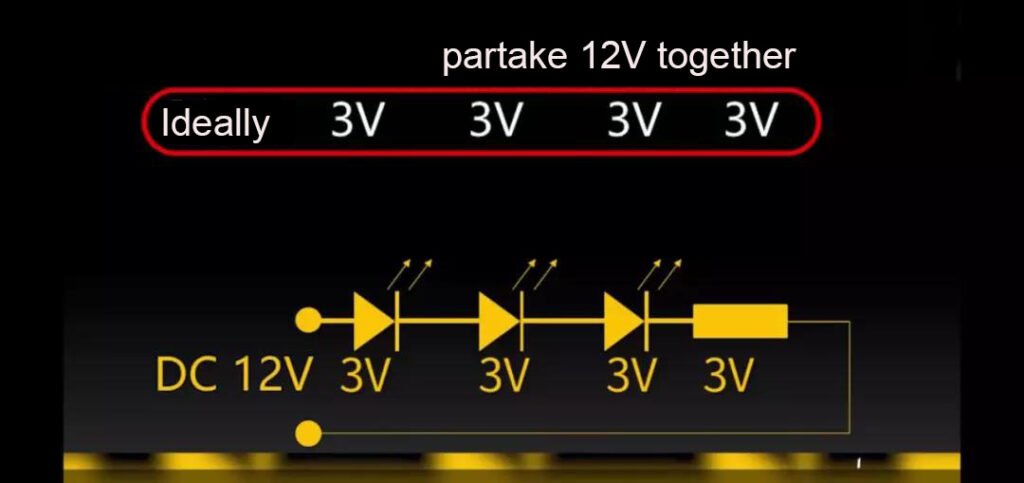

And the led strip is the same principle, for the DC12V led strip SMD2835 60LED/M, 5cm cutting unit have 3 leds and one resistor,ideally, the voltage on each component is the same, said 3V.

But in fact, the each leds is not the same, and its specification is not completely the same, and will make one led partake bigger voltage and the other leds smaller voltage as the picture as bellowed. And the leds which parttake voltage exceed 3.0V will break, and because of the series connection, the cutting unit will not work.

If the led strip need the longer lifespan and high reliability, it’s better to choose the same specification or almost same, because the AC220V led strip is 1M cutting unit and have 60led/M or more leds partake the voltage. It’s not so difficult to find the 6leds with same specification, but for AC220V to find 60pcs same specification leds would be top difficult.

What’s to do if can not find the same 60leds for AC220V led strip, only to use some different leds, so the problem happened. In order to avoid the problem of the whole unit not work, but some factory will add the “Zener diode”, when the led not work, the current will spark over the zener dioder to make the other leds working(but the leds brocken in advance is still in dark color).

General speaking, the low voltage led strip have the lifespan of 50000-100000 hours ideally, and 30000-50000hours lifespan in the actual application.

High voltage led strip because of its high voltage, the heat about one meter is higher than the low voltage led strip, which will affect the lifespan of the lifespan of high voltage led strip and 10000hours in the actual application.