Structure and components description

Neon flex cover: the led neon flex for trio view IP68 is the PU(polyurethane) materials, ensure the strip body will not apart from the cover after the long time working underwater, besides, the light will not penetrated from the back.

FPC: Double layer 2oz FPC rolled copper to ensure the neon flex have the best heat-dissipation and the excellent flexibility, so the neon can be bent for many times and the FPC will not split and brocken, and the max run for the single color can be 15M from one end without any voltage drop.

Reasonable Design: this led neonflex is consist of Philips Lumileds SMD2835 140LED/M, DC24V, the each unit is 7leds+1 resistor, with this design, the led neonflex can get the very high lumen as 890LM/M and nearly 90LM/W.

Milky PU: the milky glue filling from the bottom to the top, it’s dot-free and the IP rating is IP68 for the underwater by depth 5.8M(5.8kpa for 300 hours testing).

Resistant: UV/chlorine/salty water/high temperature resistant, and the led neonflex are the ideal solution for the underwater and outdoors project, and will not yellowish in 3 years and without corrosion on the surface.

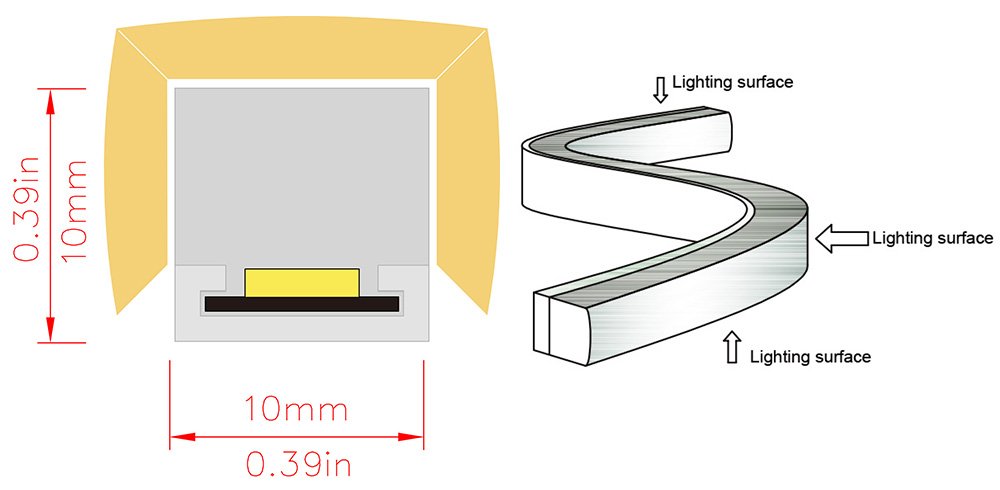

3-side Emitting/Trio view

Ultra Small Siza

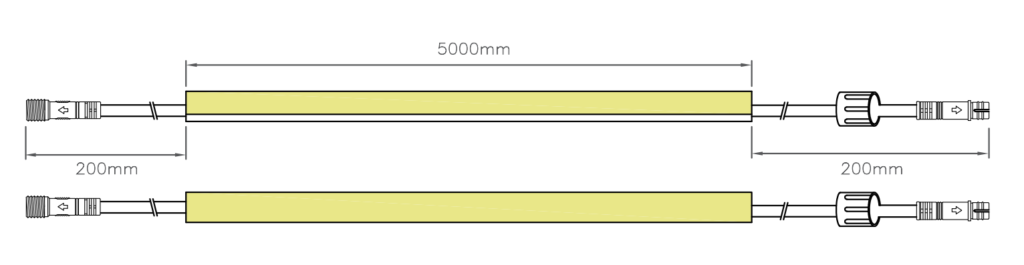

The trio view led neon flex is a small size with cross section 10x10mm and it’s length can be 10M/reel max.

Various Installation

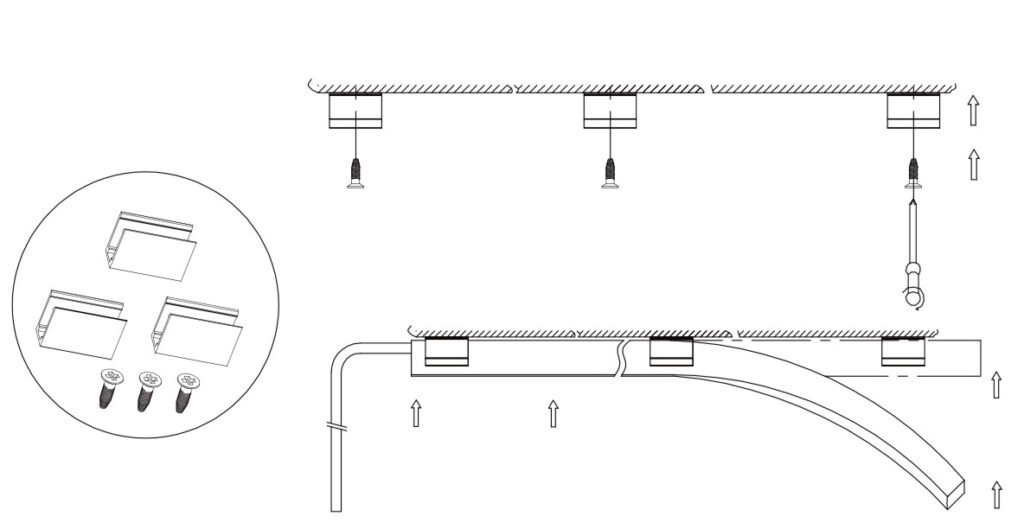

Clips Installation

1.Turn off power supply.

2.According to the actual location of the desired length, selecting the

appropriate cut position .

3.Installing the clip according to the actual length of the LED Neon Flex.

4.Installing LED Neon Flex one end into the clip, and then snap into the clip in

turn.

5.Connecting the LED Neon Flex to the power supply DC plug and the

power supply to the AC line connection.

6.Turn on the power supply.

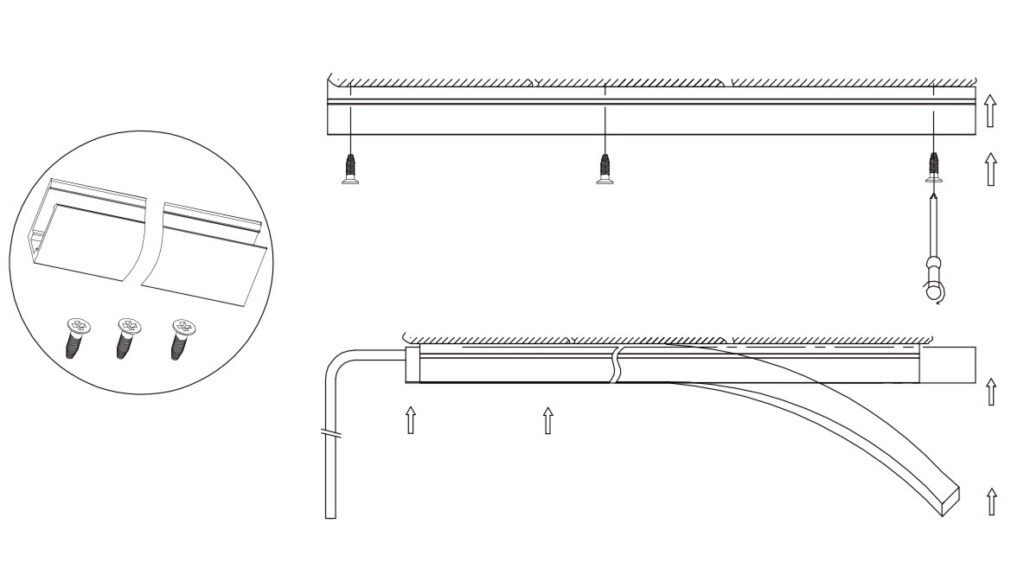

Aluminum Profile Installation

1.Turn off power supply.

2.According to the actual location of the desired length, selecting the

appropriate cut position .

3.Installing the aluminum profile according to the actual length of the LED

Neon Flex.

4.Installing LED Neon Flex one end into the aluminum profile, and then snap

into the aluminum profile in turn.

5.Connecting the LED Neon Flex to the power supply DC plug and the power

supply to the AC line connection.

6.Turn on the power supply.

Bendable Profile Installation

1.Turn off power supply.

2.According to the actual location of the desired length, selecting the

appropriate cut position .

3.Installing the flexible profile according to the actual length of the LED Neon

Flex.

4.Installing LED Neon Flex one end into the flexible profile, and then snap

into the flexible profile in turn.

5.Connecting the LED Neon Flex to the power supply DC plug and the

power supply to the AC line connection.

6.Turn on the power supply.

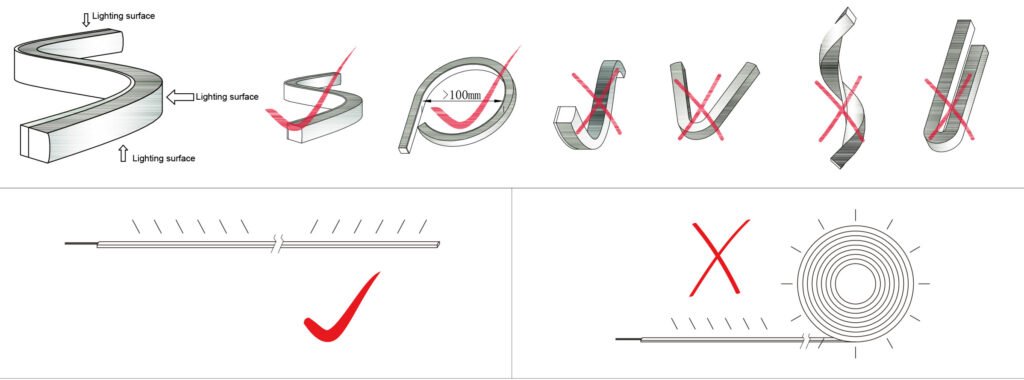

Bending Instructions

The trio view led neon flex is the top/vertical bending and its bending diameter is 100mm;

The testing should not rolled and it’s harmful to the lifespan and the product quality.

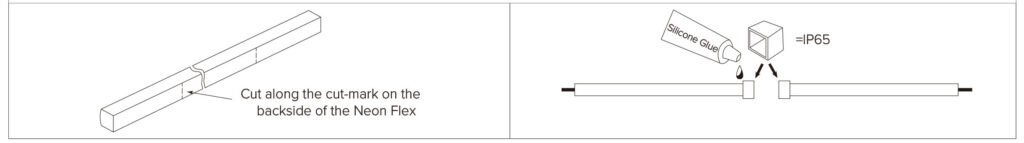

Cutting the Led Neon Flex

Cut along the cut-mark on the backside of the Neon Flex;

After the cutting and adhere the end-cap, the led neonflex is IP65 rating and can not applied for underwater lighting;

Application

The led neon flex can be applied to the cove lighting.

Facade Lighting for the outdoors building to create the special line.

Lighting for swimming pool and other projct as underwater type.

2 Responses

Every word you’ve written feels like it carries a lifetime of wisdom. There’s a clarity to your thoughts and a depth to your reflections that is rare in today’s world. Your writing isn’t just meant to be read — it’s meant to be savored, to be thought about, and to be shared with others who will appreciate its quiet beauty.

Many thanks for the comment. I will try my best to bring more high quality artice in the future.